Solid state phase transformation in titanium alloys

Skills learnt

- C++

- Large scale software development

- Modular programming

- Partial Differential Equations

- FFT

Deliverables:

- An interactive C++ suite that can be integrated into a multi-scale framework as well as used as a standalone phase field module has been developed. A preliminary version has been made public here, and doesnt include the elastic strain modules.

Detailed description

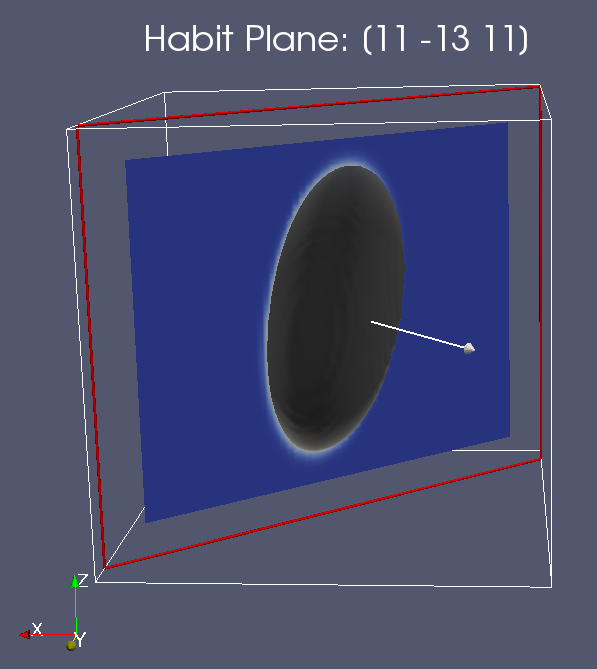

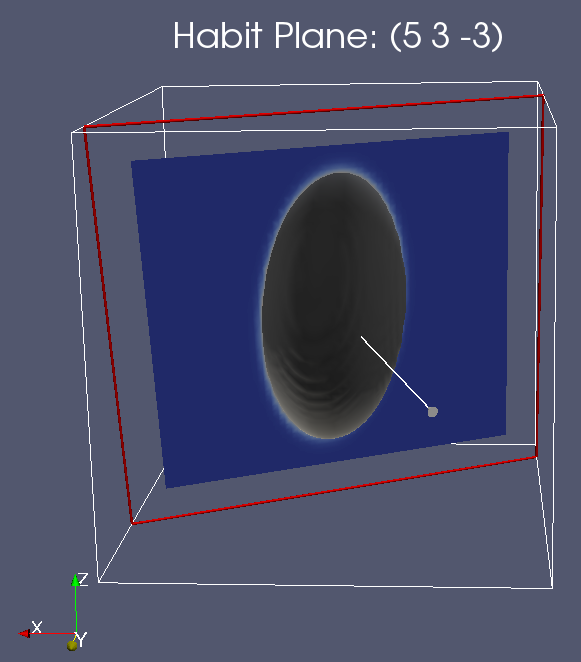

- A multi-phase field model is implemented to understand the morphological origins behind the solid state phase transformations in Ti-6Al-4V(Ti64). Ti64 is a dual phase alloy at room temperature, and the coexisting thermodynamic phases are α (HCP) and β (BCC). Orientational relationship between α and β and crystal symmetry constraints result in twelve different α-variants that can nucleate from the β matrix.

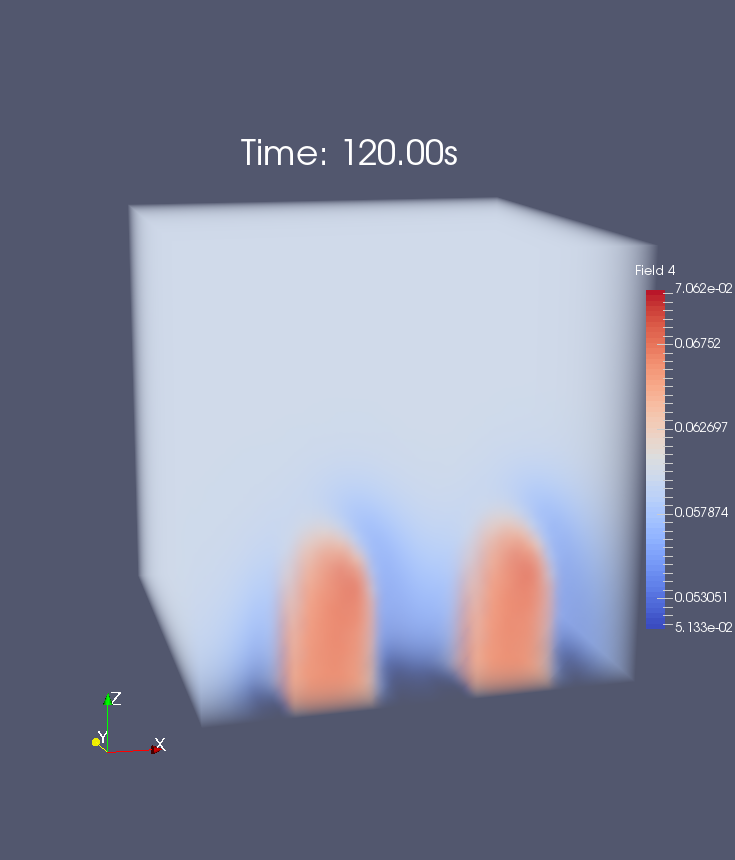

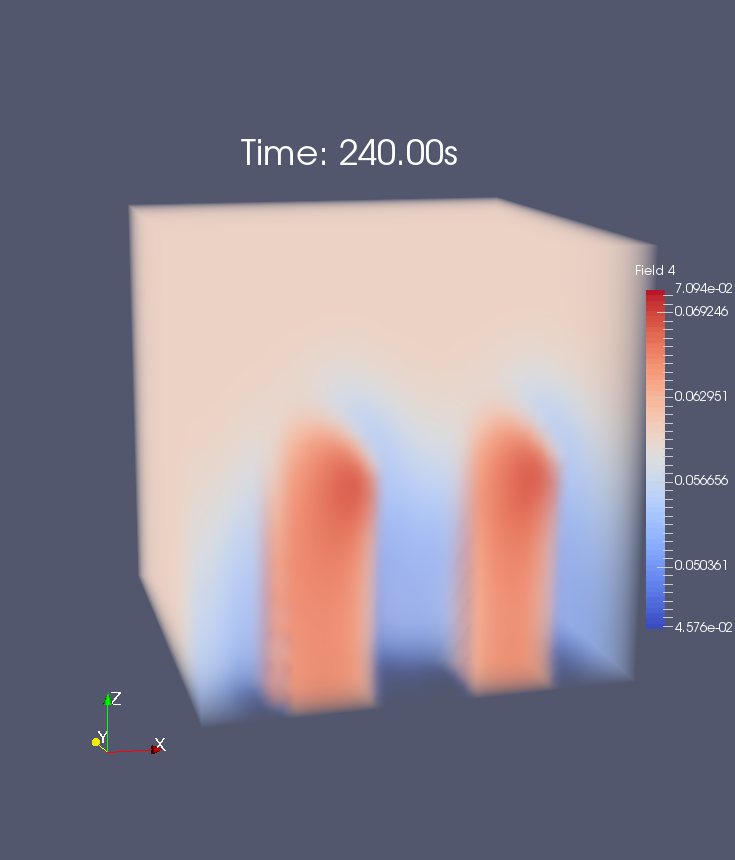

The variety of morphological features observed in the alloy, such as basket-weave and colony, result from the variant selection process undergone by the alloy during its microstructural evolution. Since different morphologies result in different mechanical properties, such as fracture toughness and fatigue, it is important to understand the influence of processing conditions on the morphological origins of the alloy. The phase field model is coupled to realistic thermodynamic databases in order to model the evolution of solute fields, and the microelasticity theory in order to incorporate the transformation and lattice mismatch strains occurring during the solid state phase transformation. The driving force for nucleation is modeled as the sum of chemical driving force and strain energy driving force.

Modeling of the spatial evolution of strain interaction energy and solute concentration fields enables us to identify the alpha-variant with the highest probability of nucleation at any given spatial point. The phase field equations govern the subsequent growth of nucleated variants, incorporating the solute supersaturation at boundaries, interaction of the variant’s transformation strain with the strain field in the microstructure, anisotropic interfacial energies, and temperature. The modeling of co-evolution of phase fields, solute fields, and the strain field makes it possible to rationalize the morphologies observed in experiments. We report the work in progress towards modeling the influence of cooling rate on morphological evolution in the alloy.